Nothing ruins a transparent acrylic display box faster than visible glue marks or bubbles. Fortunately, these issues are preventable with the right bonding techniques.

Understanding Acrylic Bonding

Acrylic boxes are typically assembled using solvent bonding, UV bonding, or two-part epoxy. Each has its pros and cons:

- Solvent bonding melts the acrylic surfaces, forming a seamless join.

- UV bonding cures clear under UV light—perfect for crystal-clear finishes.

- Epoxy bonding provides strength but may slightly yellow over time.

Causes of Glue Marks

- Using too much adhesive or uneven application

- Poor surface preparation (dust, fingerprints)

- Air trapped during bonding

- Curing too fast or too slow

Professional Tips

- Always use optically clear UV adhesive for transparent displays.

- Apply bonding in a dust-free, temperature-controlled room.

- Allow full curing time before removing protective films.

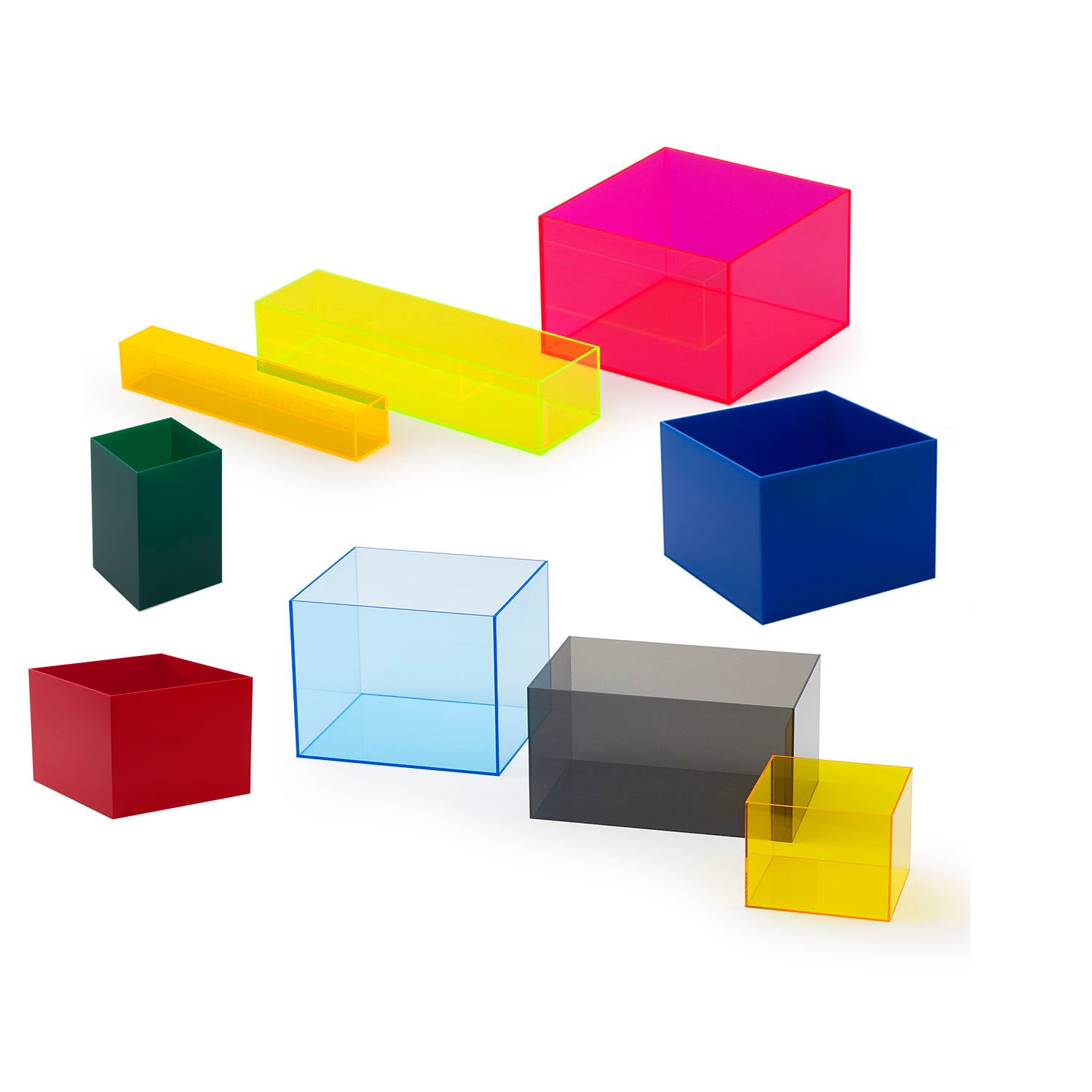

Why It Matters for Custom Orders

In custom production, visual perfection is key. A single glue line can change how a brand perceives quality. TW’s bonding process uses precision dispensing and UV tunnels to ensure every acrylic joint is flawless.